What is Ceramic Injection Moulding (CIM)?

The CIM process begins with very fine ceramic powders. The mix of dry powders are mixed in a ceramic mixer. The powders are then compounded with thermoplastic binders to produce a homogeneous feedstock, with a specially designed Ceramic mass mixer.

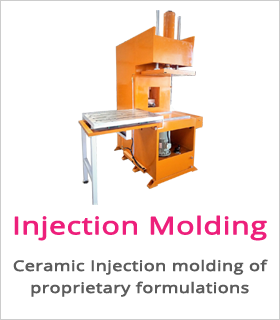

The thermoplastic binders form a liquid medium to carry the ceramic powders into the mould during injection moulding. The CIM-CxxTSA injection moulding machine is used for the purpose. the Moulds for injection can be single or multi-cavity tools.

Ceramic Injection Process

Step 1

Step 2

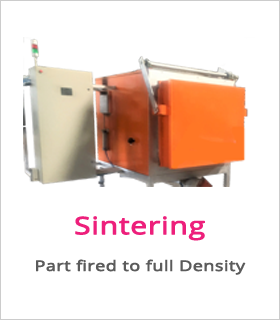

Step 3

Step 4

CIM results in forming a net shape part.After forming the part, it undergoes two thermal processes. First is Debinding, pyrolysis to remove the binder, followed by Sintering in a high temperature kiln to form a fully dense ceramic component. During sintering the component shrinks uniformly while retaining the complex shape.

With good process control close tolerances can be obtained, therefore machining of the part after sintering is usually not necessary.

These components offer all the benefits associated with technical ceramics including wear resistance, corrosion resistance, thermal stability, superior hardness, high mechanical strength and dimensional stability. Physical features available through ceramic injection moulding include undercuts, threads, blind holes and curves.